A range of breathable, non-breathable PE film and textile backsheet for hygiene products and medical products from China leading manufacturer. Excellent whole processing capability from A to Z, including materials compound, film blowing or casting, perforation, embossing, printing, and lamination. Compostable biodegradable PLA, PBAT, PPC, PHAs, PGA films are also available for your specific needs.

SUNREE has extended its range of offerings focused on varying customer needs for both product and production requirements. We go through strict processes based on product quality, strictly according to the standards to ensure consistent quality of our cast film and blown film.

Our specialists have professional experience working with many companies in personal hygiene and medical industries, and have curated a library of industry-specific custom options for you!

We offer excellent mechanical properties non-breathable polyethylene cast film which is manufactured from a mixture of polyethylene by extrusion technology, engineered for personal hygiene products. This includes baby diaper, adult incontinence briefs, sanitary napkins, pantyliner and underpads.

With polyethylene as the main component, it is a thin impermeable back sheet film that balances softness, stiffness and toughness like no other film, exceptionally thin, strong backsheet films with new levels of comfort and security using performance PE polymers.

These non-breathable films can be produced with or without surface embossing and corona treatment, using pure polyethylene and color master batch, or mixed with calcium carbonate fillers.

We offer breathable polyethylene cast film and blown film for personal hygiene products and protective equipment, including baby diaper, adult incontinence briefs, sanitary napkins, pantyliner, underpads and surgical gowns.

Our breathable PE film is composed of microporous structure which allows the transition of water vapor while it blocks the water transition itself. It is produced from a combination of polymers and calcium carbonate fillers, enhanced physical and thermal robustness, offering a wide range of breathability.

This breathable film helps to enhance user comfort, the permeability allows the skin to breathe better, reducing potential occurrence of undesired side effect such as skin rash, sores etc.

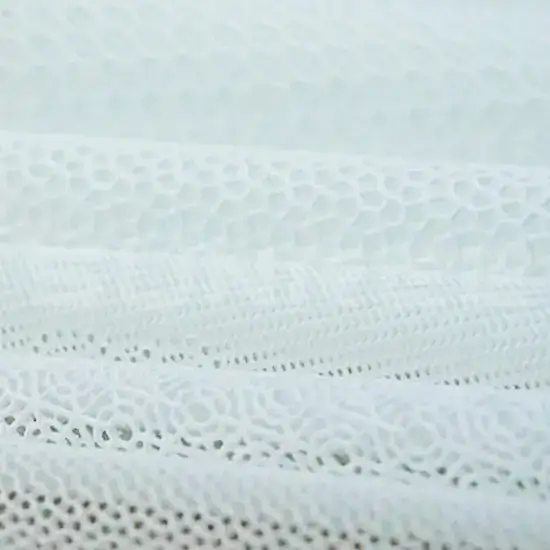

Textile backsheet, also known as cloth-like backsheet, lamination back sheet, bottom sheet for diapers, or liquid-impermeable bottom cover sheet, is produced by laminating polyethylene film on nonwoven fabric with hot melt adhesive, textile backsheet products have a soft texture similar to a textile products, these lamination back sheets are mostly used in baby diaper and adult incontinence diaper.

Printing which is shaped depending on preferences is possible up to 8 colors on the polyethylene film, it can be non-breathable or breathable PE film. A range of nonwoven fabrics can be chosen, like PP spunbond nonwoven and hot air through nonwoven fabric.

Textile breathable backsheets prevent the passage of liquid, the passage of air and it can be achieved by the film that uses water vapor transmission.

Embossed PE film, also known as gravure film, micro-embossed film, or deep embossed film, is produced from different polymers using chill roll with a gravure application and cast film process.

It is mostly used as the back sheet of baby diaper, adult briefs, sanitary napkins and underpads, with or without air permeability function. The structure with anti-infiltration and anti-pollution effects, avoiding the penetration of the liquid completely.

Apertured 3D film, also known as perforated film or micro-perforated film, uses polyethylene materials, while the melt resin comes out of the extrusion die, it is formed into film and vacuum perforated. Lamination perforated film is also available.

Classic perforated polyethylene film in different shapes, like square, circular, pentagonal, elliptical, etc. with low basic weight, which help facilitate absorption and allows fluid to pass freely into the interior of absorbent core, but which inhibits the reverse or outward flow of fluid.

It is mostly used as the top sheet of sanitary napkins and pantyliner. The topsheet comprises a three-dimensional hydrophilic formed film having a plurality of openings leading from a surface of the topsheet to an absorbent core, it presents a more comfortable and dryer surface which contacts the wearer and a clean, dry appearance to the wearer.

We are a company that values customers’ satisfaction. We always aim at supplying and delivering quality products that meet the demand of high-quality hygiene products manufacturers. SUNREE is able to lead you by hand in your hygiene product business everywhere. With 16+ years of experience, SUNREE is well versed in this field.

These frequently asked questions mention almost answers you might want to know before buying PE film. We hope these informations could help you make a better decision.

Polyethylene film is a plastic film made from ethylene, a hydrocarbon which is mainly obtained from natural gas or petroleum. The polyethylene is abbreviated as PE, the main process technology is casting or blowing method. PE film can also be manufactured in breathable or non-breathable types with different color and printing. In addition, it can be different basic weight.

PE cast method is one of PE film processing method. Cast film is a non tensile and non directional flat extruded film produced using a cast extrusion process, in which the polymer discontinuously pumping through a straight slot. Available in single-layer and multi-layer co-extrusion methods.

PE blowing method is one of PE film processing method, melting plastic particles by heating, then blowing them into membrane. It usually extrudes the polymer into a tubular film, blowing the tubular film to the required thickness by high-pressure air in a better melt flow state, cooling and forming into thin film.

Blown film has more even glossiness and clean color, more softer, and better tensile strength. The testing result as below:

Non breathable film is non-porous structure, without stretching process. It restricts water flow, airflow and water vapor. It can be one side or both sides corona treatment. It is mainly used in hygiene industry as back sheet film of baby diaper, adult diaper, underpads and feminine pads, pouch film of sanitary napkins.

Breathable film is also known as waterproof and breathable microporous membrane, which is characterized by breathability and impermeability. It is produced from breathable beads (PE and treated CaCO3 compound). The microporous membrane has countless interconnected micropores with ultrafine pores, about 0.01-10 micros, which can only pass through the vapor molecules with the particle size of about 0.4nm, while any raindrops or water droplets cannot pass through because of its particle size. In this way, the water vapor emitted by the human body can effectively diffuse outward through the pores, while the water droplets cannot penetrate inward, thus achieving the effect of waterproof and moisture permeability. It is widely used in hygiene and medical industry as the back sheet of baby diaper and pull-up diaper, and laminated with nonwoven fabric for back sheet and isolation gown.

Inorganic fillers (e.g. calcium carbonate, talc), are added to the raw materials, the micropores are formed where the inorganic fillers (1-10 microns) combine with the film substrate being shaped during the stretching process. These micropores are sub-nanometer in size, hundreds of millions of micropores can be distributed over an area of 1 square centimeter, and these micropores allow the vapor to pass through, thus achieving breathable but impermeable properties.

It is used for a wide range of applications in disposable personal hygiene products and medical products, such as adult and baby diapers back sheet, sanitary napkins back sheet, underpads backsheet, pantyliner backsheet, top sheet of sanitary pads and pantyliner, small pouch film of sanitary napkins, bandage, medical fixing tape, isolation gowns.

We are pleased to send you samples to test the quality. We are confident that once you get it in your hand, you will be very satisfied.

Once clear your requirement and determine which product is ideal for you, we will send you official proforma invoice. Payment terms can be TT bank transfer, L/C, Paypal, etc.

Wrapped with PE film and enclosed by corrugated kraft headers designed to be suitable for long-distance transportation to be well protected against dampness, moisture, and rough handling.

Special packaging can be requested by you.

Please don’t hesitate to confirm with us for the design of PE film. We always keep a stock of regular white color PE film, there is no MOQ requirement. For specific pattern printing, MOQ is 3000kgs, one 20fcl can be loaded about 20tons.

We are rich experience in exporting. FOB, CFR, CIF, DDP, DAP delivery terms can be accpeted, or as your wish.

For the new design, the lead time of PE film will be 2-3 weeks after receiving the deposit or 100% payment into our bank account, lamination film should be 3-4 weeks from platemaking to lamination process.

If we have the printing plate of the design already, it can be within 1-2 weeks, lamination film should be 2-3 weeks.

We can ship in small batches by way of air express or larger ones by the container, and mix loading with some other items in one container. To save costs, you can either use your own assigned shipping agent or our cooperative forwarder.

Please don’t forget that we are located in the coastal areas of China, which means that we have the most convenient maritime transportation!

We have helped customers in more than 60 countries to be successful, our website hereby lists some of the products we have successfully supplied. Please note that this constitutes just a tip of the iceberg of our products and innovations. If you prefer, get in touch via the Contact Us section.

Please tell us what kind of support you need, we will reach out to you within 1 working day, please pay attention to the email with the suffix “@sunreehygiene.com”.