Introduction

Ever wondered how those trusty disposable baby diapers are made? From fluff pulp to excellent super absorbent polymers, or use ultra-thin absorbent paper core, the manufacturing process is a fascinating blend of science and innovation that keeps babies dry and parents happy. Baby diapers, also known as baby nappies, infant diapers. In this comprehensive guide, we’ll take you through every step of how disposable baby diapers are created, explore the essential raw materials involved, and highlight how SUNREE, one of the leading manufacturers and suppliers in the hygiene industry for over 18 years, supports businesses in producing top-quality baby diapers. Whether you’re a curious parent wanting to know what’s in your baby’s diaper or a business looking to partner with a reliable supplier, this article has something for you!

Disposable baby diapers are more than just a convenience—they’re a marvel of modern engineering. Each baby diaper is designed to be absorbent, comfortable, and leak-proof, all while being produced at scale to meet global demand. At SUNREE, we’ve been part of this journey since 2007, supplying cutting-edge manufacturing machines and cost-effective raw materials to companies in over 60 countries. Our expertise ensures that every baby diaper meets the standards, balancing performance with sustainability. Stick with us as we dive into the process, from raw materials to finished product, and discover why SUNREE is your go-to partner in the hygiene industry.

For a deeper look at how baby diapers have evolved and their impact on daily life, check out this external resource: How Disposable Diapers Are Made. Ready to explore the process? Let’s get started!

What is the Disposable Baby Diaper Manufacturing Process?

The disposable baby diaper manufacturing process is a carefully orchestrated sequence of steps that transforms raw materials into the reliable baby diapers we use every day. At its core, it involves five key stages: forming the absorbent core, preparing nonwoven layers, assembling the components, adding elastic bands, and ensuring quality through testing and packaging. Each step is critical to creating a baby diaper that’s absorbent, comfortable, and leak-proof—ready to tackle the messes of babies worldwide.

First, the absorbent core is crafted from fluff pulp and superabsorbent polymers, or ultra-thin absorbent paper instead of fluff core, wrapping with hydrophilic nonwoven or excellent wet strength carrier tissue, creating the heart of the baby diaper’s leak-fighting power. Next, nonwoven layers are prepared to form the soft and hydrophilic top sheet and waterproof back sheet, back sheet consist of hydrophobic nonwoven and breathable PE film, sandwiching the absorbent core. Then, all components are assembled into a single unit, complete with fasteners like adhesive tape or hook tape. Elastic bands are added for a snug fit, and finally, rigorous quality checks ensure every baby diaper meets strict standards before being packed for distribution. It’s a process that combines precision machinery with high-quality materials, and at SUNREE, we provide both—explore our products to see how.

This streamlined process has made disposable baby diapers a global staple, with production lines churning out millions of units daily. Curious about the machines behind it all? Visit our machines section to learn more about the technology driving diaper production. Let’s break it down further in the next section!

Introduction to Disposable Baby Diaper Manufacturing

Disposable baby diapers have revolutionized parenting since their introduction in the 1940s. What began as simple cellulose pads tucked into rubber pants has grown into a high-tech industry boasting over 1,000 design patents. Today, baby diapers are a blend of advanced materials and engineering, making them a household essential. In 2024, the U.S. diaper industry alone is valued at $14.7 billion, while the global market is projected to hit $100.94 billion by 2031, growing at a steady 4.37% annually. That’s a testament to how indispensable these little wonders have become!

At SUNREE, we’ve been shaping this industry since 2007. With 18 years of experience, we’ve empowered businesses in over 60 countries with top-tier manufacturing machines, premium raw materials, and innovative packaging solutions. Our goal is simple: to help create diapers that are high-quality, affordable, and eco-conscious. We’re not just suppliers—we’re partners in innovation, supporting every stage of production from raw materials to finished goods.

The journey of a diaper starts with raw materials like wood pulp and polymers, moves through sophisticated assembly lines, and ends with a product that keeps babies comfortable around the clock. It’s a process that’s both an art and a science, and we’re proud to be at its forefront. For more on the diaper industry’s growth, check out this external report: Diaper Market Size & Forecast. Let’s dive into the materials that make it all possible next.

Key Materials and Their Roles

Disposable diapers might seem simple, but they’re made from a carefully selected mix of materials, each playing a vital role in performance and comfort. Let’s break down the key players and how they work together to keep babies dry and happy.

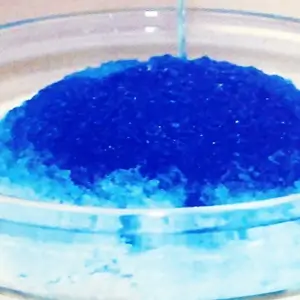

Absorbent Core: This is the diaper’s MVP. Made from fluff pulp and superabsorbent polymers (like sodium polyacrylate), it can absorb 400-600 times its weight in liquid. That’s why babies can go hours without a change! The fluff pulp provides structure, while the polymers lock moisture away, keeping skin dry.

Top Sheet: This soft, permeable layer of nonwoven fabric sits against a baby’s skin, normally use spunbond nonwoven or hot air through bonding nonwoven. It lets liquid pass through to the absorbent core while staying gentle and dry to the touch—like a cozy, breathable blanket. Our nonwoven fabrics are designed for comfort and durability.

Back Sheet: Made from impermeable polyethylene, this layer is the diaper’s waterproof shield. It prevents leaks, keeping clothes and cribs clean. Check out our backsheet materials for leak-proof perfection.

Elastic Bands: Stretchy synthetic rubber bands around the legs and waist ensure a snug, leak-free fit. They flex with movement, offering comfort and security. We provide hot melt adhesives to bond these elastics material seamlessly.

These materials are the building blocks of every diaper, and at SUNREE, we supply them all. From absorbent cores to hook and loop fasteners, we’ve got you covered.

The Manufacturing Process: Step-by-Step

Now, let’s walk through how a disposable baby diaper comes to life. This five-step process combines precision, technology, and quality materials to create a product trusted by millions. Here’s how it happens.

Step 1: Forming the Absorbent Core

Picture a fluffy cloud forming on a conveyor belt. Fluff pulp is shredded and mixed with superabsorbent polymers, then sprayed onto a moving surface. A vacuum pulls it into a flat, uniform pad—the diaper’s absorbent core. This step is all about balance: too much polymer makes it stiff, too little reduces absorbency. Our manufacturing machines ensure the perfect mix for a pad that soaks up messes like a pro.

Step 2: Preparing the Nonwoven Layers

Next up are the nonwoven fabrics—the diaper’s “skin.” Plastic resins (normally polypropylene for the top sheet, polyethylene for the bottom) are melted, extruded into thin sheets, and rolled out. The top sheet stays soft and permeable, while the back sheet—our backsheet—keeps leaks at bay. These layers are critical for comfort and protection, and our nonwoven fabrics deliver both.

Step 3: Assembling the Diaper Components

Think of this as building a sandwich. The absorbent core is placed between the top and back sheets, sealed with heat or hot melt adhesives. Fasteners like loop tape or hook and loop closures are added, and the long strip is cut into individual diapers. Precision here is key—our equipment ensures every piece fits perfectly.

Step 4: Adding Elasticity for a Snug Fit

Elastic bands are stretched and glued along the diaper’s edges. When they relax, they create a snug fit around the legs and waist—like a gentle, leak-stopping hug. This step boosts comfort and performance, and our adhesive solutions make it seamless.

Step 5: Quality Control and Final Packaging

Every baby diaper gets a final check. Tests like Absorbency Under Load (AUL) ensure it holds at least 24 ml/g of liquid under pressure. Once approved, baby diapers are folded, stacked, and packed using our packaging solutions. Only the best make it to families!

Environmental Considerations

Diaper manufacturing has a big environmental footprint. In the U.S. alone, it consumes over 200,000 trees and 3.4 billion gallons of fuel annually. Plus, billions of diapers—made with slow-degrading polyethylene—end up in landfills each year, contributing over 3.5 million tons of waste. It’s a challenge the industry can’t ignore, but change is underway.

Innovations are making diapers greener. Biodegradable materials, like plant-based polymers, are reducing reliance on fossil fuels. Smarter designs have cut material use by 23% and energy consumption by 10% in recent years. At SUNREE, we’re committed to sustainability, offering eco-friendly raw materials and efficient machines that minimize waste. We’re helping businesses create diapers that are kind to both babies and the planet.

For more on the environmental impact, see this external study: Environmental Impact of Disposable Diapers. Learn about our green initiatives in our insights section.

Industry Statistics and Market Trends

The diaper industry is thriving, driven by demand and innovation. Here’s a snapshot of key stats:

| Category | Statistic |

|---|---|

| US Industry Revenue (2024) | $14.7 billion |

| Global Market by 2031 | $100.94 billion |

| EU Annual Production | Over 20 billion units |

| AUL Test Standard | Absorb at least 24 ml/g under pressure |

Growth is strong, especially in regions with rising birth rates, but even in mature markets, thinner designs and eco-friendly options keep demand high. SUNREE supports this boom with solutions for businesses worldwide—explore our products to see how we’re shaping the future of hygiene.

For a deeper dive, check out: Diaper Market Size & Forecast.

Common Questions About Diaper Manufacturing

Got questions? We’ve got answers based on our 18 years at SUNREE:

What are the environmental impacts? Production uses trees and fuel, and landfills see over 3.5 million tons of diaper waste yearly in the U.S. But greener materials are helping—see our insights.

How are materials chosen? Absorbency (polymers), comfort (nonwovens), and cost drive choices, often with a 75:25 fiber-to-polymer ratio.

What’s new in diaper manufacturing? Thinner, more absorbent, and eco-friendly designs are trending.

How are diapers made leak-proof? Waterproof backsheets, elastic spandex, hydrophobic nonwovens, and tight seals do the trick.

What ensures quality? Rigorous tests like AUL guarantee performance.

Why Choose SUNREE for Your Hygiene Product Needs?

Tailored Solutions: We customize machines, materials, and packaging to fit your needs.

Top Quality: Strict checks ensure every product shines—babies deserve the best.

Trusted Support: Our team brings expertise and care to every partnership.

Super soft nonwovens for diaper comfort.

Absorbs 400-600 times its weight!

Secure bonding for a perfect fit.

Get Started: Ready to elevate your baby diaper production? Visit SUNREE today!

Conclusion

From raw materials to store shelves, the disposable diaper manufacturing process is a blend of creativity, precision, and innovation. It’s an industry that’s growing fast, embracing sustainability, and keeping babies comfortable worldwide. At SUNREE, we’re proud to lead the way with cutting-edge machines, premium materials, and a passion for quality. Whether you’re a manufacturer or just curious, we hope this guide has shed light on the fascinating world of diaper production.

Ready to take the next step? Partner with SUNREE to create diapers that stand out. Explore our offerings, from nonwoven fabrics to packaging solutions, and see how we can help your business thrive. Visit SUNREE today—let’s build a better future for hygiene together!