HYGIENE FILMS AND TEXTILE BACKSHEET

FOR ALL YOUR HYGIENE PRODUCT NEEDS

A range of breathable, non-breathable cast and blown PE film, textile backsheet, compostable biodegradable films for your product needs, they are used in key components of baby diaper, feminine hygiene pads, and adult incontinence products.

EXPERIENCE YOU CAN RELY ON

Hygiene and personal care products are subject to the highest requirements in terms of safety, reliability, discretion, and innovation. With decades of experience in designing, developing, manufacturing, and supplying high-performance barrier film solutions for personal care products – from newborn to old, SUNREE is one of the most trusted partners in the personal care field.

Our portfolio for personal care includes cast and blown PE film, textile back sheet, perforated film, and biodegradable film, which provide thin yet durable, tough yet discreet, maximum protection and comfort.

PRODUCTS

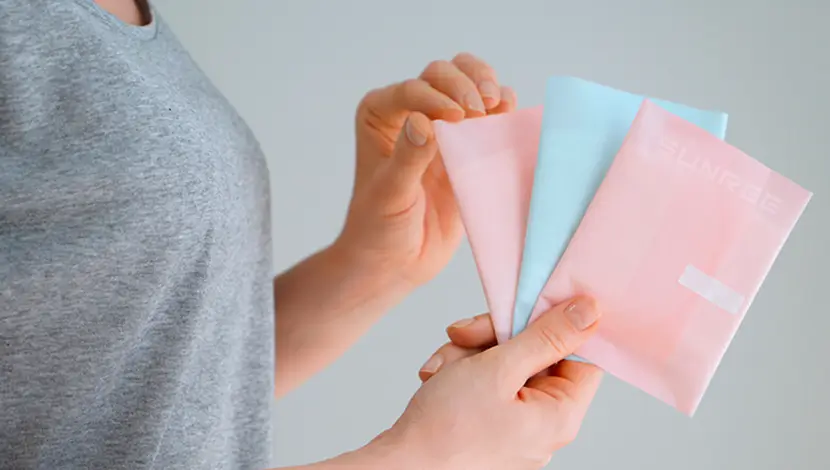

Our backsheet film, topsheet film, and pouch film for disposable baby diaper, feminine sanitary pads, pantyliners, adult incontinence briefs and underwear, and underpads allow converters and brand owners to be comfortable and confident.

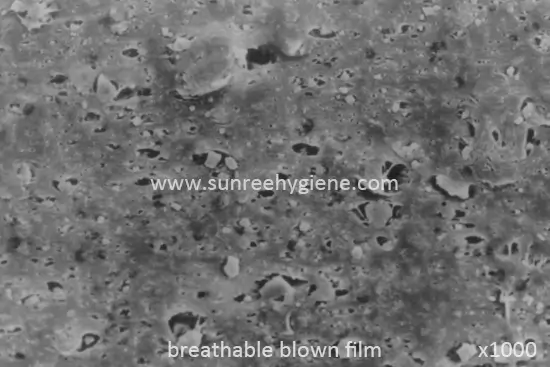

Breathable PE Film features a microporous structure that allows the transition of water vapor while it blocks the water transition itself. It provides a wide range of breathability, enhances user comfort, and allows the skin to breathe better. As a result, it helps minimize the risk of undesired side effects such as skin rash, sores, and other related issues.

Non-breathable PE Film is produced from a mixture of polyethylene by extrusion technology, engineered for personal care hygiene products. It is ideal for back sheets and single wrappers of adult baby diapers, sanitary pads, and underpads. It strikes an optimal balance of softness, stiffness, toughness, and excellent liquid repellency.

Textile Backsheet also known as laminated film, is produced by laminating polyethylene film onto a nonwoven using hot melt adhesive. It is widely used in baby diapers and adult incontinence briefs. It features a soft, texture-like texture while effectively preventing liquid penetration. Additionally, using breathable film can enhance user comfort.

Apertured Film also known as perforated film, is made from polyethylene, the molten resin is extruded through a die, forming a film that is then perforated. It helps facilitate absorption and allows fluid to pass freely into the interior of absorbent core. It is mostly used as top sheet and acquisition distribution layer of sanitary napkins and pantyliner.

Biodegradable Film, compostable, biodegradable, sustainability

Applications

Our products are key components in manufacturing disposable absorbent products like baby diapers, feminine sanitary pads, adult incontinence briefs and underpads.

- ① Topsheet

- ② Leg cuff

- ③ Elastic spandex

- ④ ADL

- ⑤ Absorbent core

- ⑥ Core wrapping

- ⑦ Backsheet

- ⑧ Waistband

- ⑨ Side tape

- ⑩ Frontal tape

BABY CARE

Babies’ tender skin deserves experience and care. For over 18 years, SUNREE has been producing performance backsheet film solutions for baby diaper, baby pants, bedpads and swim pants.

- Breathable and non-breathable backsheets

- Centre or fully lamination textile backsheets

- Compostable, biodegradable backsheets

Feature & Benefit

- Excellent shrinkage control

- High to low breathability levels (WVTR, ASTM E96)

- High quality multi-color registered printing

- Printing available with repeat-stable graphics, A/B pattern, wetness indicator

- Balanced MD CD strength, stiffness/toughness properties

- Excellent barrier

feminine hygiene

Freedom every day for women to do whatever they want, whenever they want. SUNREE is the leading expert in top and backsheet films for improving ladies’ sanitary pads, pantyliners, and protective underwear.

- Plain or embossed breathable and non-breathable backsheets

- Perforated film for top sheet and acquisition distribution layer

- Siliconized and non-siliconized film for individual packaging

- Compostable, biodegradable backsheets and pouch film

Feature & Benefit

- Multi-color and printing are available

- Excellent MD CD strength and hydrostatic

- Discretion and comfort

- Sustainability through continuous innovation

adult incontinence care

Adults deserve everyday life to be easier. Our solutions enable our customers to improve light, medium, and heavy incontinence care products, including open briefs, underpads, light incontinence pads, and protective underwear.

- Breathable and non-breathable backsheets

- Fully lamination textile backsheets

Feature & Benefit

- Multi-color and printing are available

- Excellent MD CD strength and hydrostatic

- Discretion and dependability

- Comfort and roubustness

Technology

It is an integrated one-stop process, down to the smallest detail – from raw material to final product. We are always striving to develop lighter, thinner, stronger yet softer, more protective solutions that consumers can have confidence in wearing.

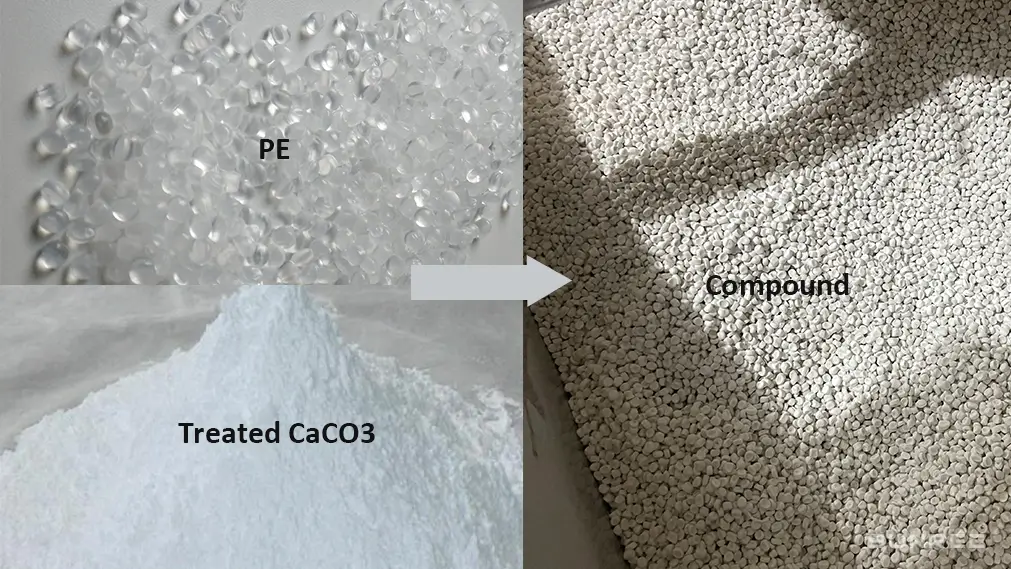

- Selection of high grade raw materials from Exxon Mobil, Dow, Sinopec, A.Shulman, Imery, Omya.

- Integrated breathable particles compounding system, including calcium carbonate treatment, compunding, extruder and pelletizer.

- Advanced cast lines and WH membrane blowing machines.

- Inline inspection vision system, thickness gauge and constant tension control, hole detection accuracy reach 0.38sqmm.

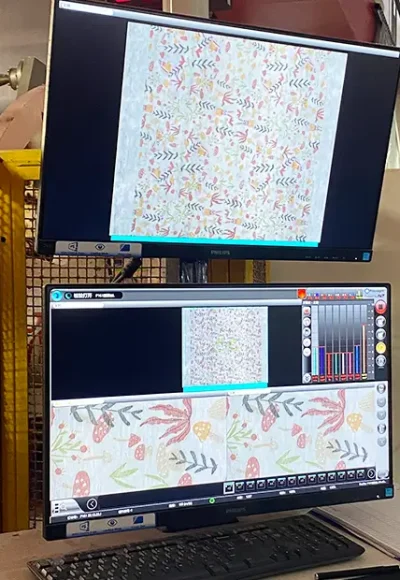

- International leading flexo and gravure printing machines, 100% inline vision system, automatic pitch length control, registration accuracy can be less than 0.3mm.

- Auto mark the defect online, roll rewinding inspection system

Manufacturing Process

It is a long way from resin to final product in PE film and textile backsheet manufacturing process and attention to detail in every link of the chain is required.

Raw material preparation

- Polyethylene resin selection, choose HDPE (High-Density Polyethylene), LDPE (Low-Density Polyethylene), or LLDPE (Linear Low-Density Polyethylene) based on product requirements.

- Additives mixing, incorporate additives like anti-static agents, slip agents, toughening agents, or masterbatches for color or functional enhancements.

Extrusion process, PE films are primarily manufactured using two methods:

- Blown film extrusion: polyethylene resin is melted and extruded through a multi-screw extruder. The molten material passes through an annular die, where air inflates it into a bubble. The bubble is then stretched, cooled, and wound into rolls. It is ideal for producing high-strength, multi-functional films.

- Cast film extrusion: the molten material is extruded through a flat die to form a thin film, and then cooled on a chill roll, and stretched to achieve the desired breathability. It is ideal for breathable, non-breathable, and laminated films.

- Breathability enhancement, inorganic fillers (e.g., calcium carbonate) are mixed with PE for compounding, followed by mechanical or thermal stretching to create micropores, imparting breathability.

- Lamination is applied to improve textile-like texture and strength properties, often used to bond with spunbond and air through nonwovens.

- Custom patterns can be printed on the film using flexographic or gravure printing techniques.

Cutting and roll-up, the film is scanned by cameras for quality control before being rolled onto shafts in large jumbo rolls, and subsequently slit into smaller rolls of the required width and packaged according to customer requirements.

QUALITY

Superior product quality is nothing but a good standard. It is reliability in every step of the process that is hard to come by.

We have formalized our working processes, and nine inspection process. We have developed a system ensuring best in class quality assurance, product quality and quality logistics.

The result is accountability and traceability through every step of the production process – from raw material to final delivery.

We have the right technology and machinery, but it is responsible and quality-conscious employees in every link of the value chain that ensures our customers the high quality they expect in our products and services.

Continual improvements are necessary to exceed the expectations of our customers.

We honour customer expectations with regards to our products and services and ensure compliance with relevant legislation and statutory requirements.

To strengthen our market position and enhance our competitiveness, we are committed to:

- Working with continual improvements

- Exceeding the demands and expectations of our customers

- Specifying and communicating raw material quality with our suppliers

- Maintaining high quality throughout the value chain

Through information, education and training, we wish to ensure that all our employees:

- Are quality conscious and take responsibility for their own work

- Have the right and obligation to react to defects

The FAQs You Might Want To Know

These frequently asked questions mention almost answers you might want to know before buying PE film. We hope these informations could help you make a better decision.

What is polyethylene film?

Polyethylene film is a plastic film made from ethylene, a hydrocarbon which is mainly obtained from natural gas or petroleum. The polyethylene is abbreviated as PE, the main process technology is casting or blowing method. PE film can also be manufactured in breathable or non-breathable types with different color and printing. In addition, it can be different basic weight.

What is PE cast processing method?

PE cast method is one of PE film processing method. Cast film is a non tensile and non directional flat extruded film produced using a cast extrusion process, in which the polymer discontinuously pumping through a straight slot. Available in single-layer and multi-layer co-extrusion methods.

What is PE blowing processing method?

PE blowing method is one of PE film processing method, melting plastic particles by heating, then blowing them into membrane. It usually extrudes the polymer into a tubular film, blowing the tubular film to the required thickness by high-pressure air in a better melt flow state, cooling and forming into thin film.

What is performance difference with cast film and blown film?

Blown film has more even glossiness and clean color, more softer, and better tensile strength. The testing result as below:

What is PE non-breathable film?

Non breathable film is non-porous structure, without stretching process. It restricts water flow, airflow and water vapor. It can be one side or both sides corona treatment. It is mainly used in hygiene industry as back sheet film of baby diaper, adult diaper, underpads and feminine pads, pouch film of sanitary napkins.

What is PE breathable film?

Breathable film is also known as waterproof and breathable microporous membrane, which is characterized by breathability and impermeability. It is produced from breathable beads (PE and treated CaCO3 compound). The microporous membrane has countless interconnected micropores with ultrafine pores, about 0.01-10 micros, which can only pass through the vapor molecules with the particle size of about 0.4nm, while any raindrops or water droplets cannot pass through because of its particle size. In this way, the water vapor emitted by the human body can effectively diffuse outward through the pores, while the water droplets cannot penetrate inward, thus achieving the effect of waterproof and moisture permeability. It is widely used in hygiene and medical industry as the back sheet of baby diaper and pull-up diaper, and laminated with nonwoven fabric for back sheet and isolation gown.

Why is PE film breathable?

Inorganic fillers (e.g. calcium carbonate, talc), are added to the raw materials, the micropores are formed where the inorganic fillers (1-10 microns) combine with the film substrate being shaped during the stretching process. These micropores are sub-nanometer in size, hundreds of millions of micropores can be distributed over an area of 1 square centimeter, and these micropores allow the vapor to pass through, thus achieving breathable but impermeable properties.

What is PE film mostly used in?

It is used for a wide range of applications in disposable personal hygiene products and medical products, such as adult and baby diapers back sheet, sanitary napkins back sheet, underpads backsheet, pantyliner backsheet, top sheet of sanitary pads and pantyliner, small pouch film of sanitary napkins, bandage, medical fixing tape, isolation gowns.

Table of Contents

LOOKING FOR SOMETHING ELSE?

We have helped customers in more than 60 countries to be successful, our website hereby lists some of the products we have successfully supplied. Please note that this constitutes just a tip of the iceberg of our products and innovations. Our engineering team could develop specifically for you, please allow us to do this.

If you haven’t been able to find a product for your exact requirements, please contact us.