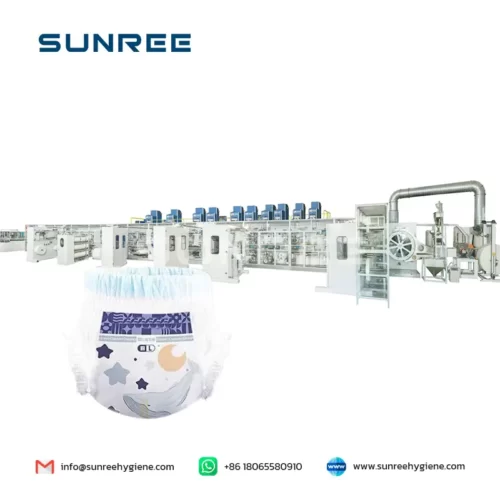

Automatic Spunbond Hot Air Topsheet Nonwoven Perforating and Embossing Machine

Additional information

| Production Speed | 70-90 meters per minute |

|---|---|

| Automation | Auto chaging roll and splicing outfeed and infeed without speed down |

| Power Consumption | approx. 200-300WH/10-12hours |

| Machine Dimension | approx. 6×2.5×2.4meters |

| Jumbo Roll Outer Diameter | 1200mm |

| Finished Roll Outer Diameter | 1050mm, or customized |

| Inner Core Diameter | 3/6 inch |

| Pattern | Customized on request |

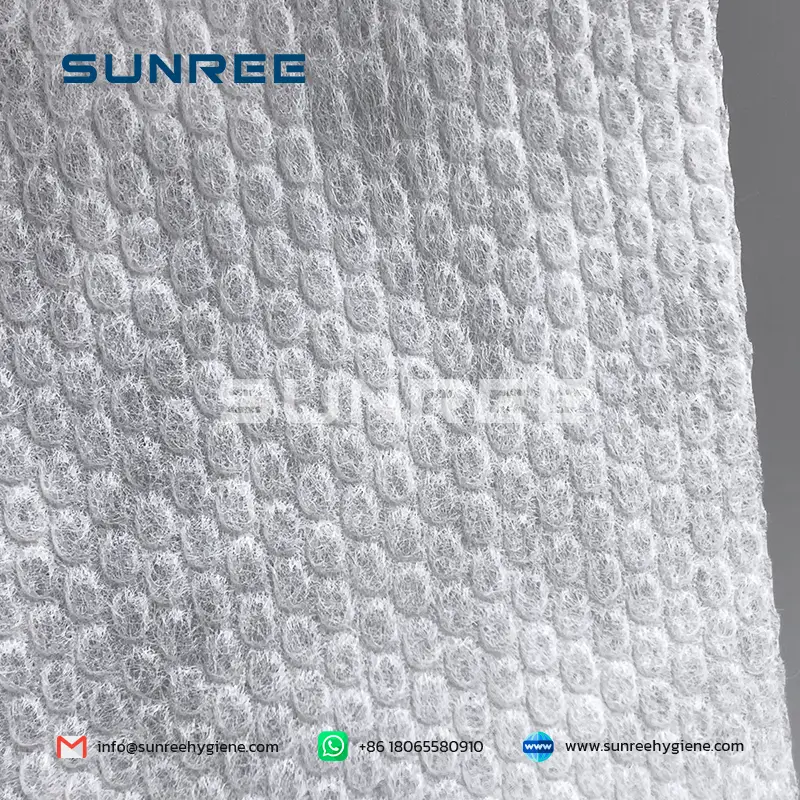

| Finished Product | Embossed Nonwoven, Perforated Nonwoven, Aperturing Nonwoven |

Share:

Automatic Spunbond Hot Air Topsheet Nonwoven Perforating and Embossing Machine

Product Details:

Main Parameters and Benefits

- Double-shaft material rest, auto A/B axis unwinding by servo control with constant tension control, equipped with twice tension

- Automatic changing roll and splicing without speed down to minimize material waste, and enhance production efficiency to reduce labor cost and power consumption

- Dual motion control roll winding technology ensures “holes-to-holes” precision, and flatness on both sides of the nonwoven roll

- Easy to control the tightness of roll winding, suitable for kinds of nonwovens, especially for hot air through ATB nonwoven

- Easy to change the embossing and perforating mold roller, to minimize downtime

- Big roll diameter is workable, max. 1050mm or customized, reduce the material splicing during the production

- Low power consumption, approx. 200-300KW/10-12hours according to the width and pattern

- Production speed: 70-90 meters per minute (according to the embossed pattern)

- Machine dimension: approx. 6 x 2.5 x 2.4m

Finished Product Specifications

- Jumbo Roll unwinding diameter: 1200mm

- Jumbo Roll width: 1250-1650mm, or customized

- Inner core diameter: 76 or 152mm

- Finished roll diameter: 1050mm, or customized

- Roll width: 65-1600mm, or customized

Related products

-

Diapers Sanitary Napkins Pads Ultra-thin Absorbent Core SAP Paper Sheet Making Machine

Read more -

High Speed Disposable Compressed Towel Tablets Making Machine

Read more -

High Speed Full Servo Q-type Baby Pull-ups Pant Diaper Manufacturing Machine

Read more -

Full Servo Automatic Adult Pull-ups Diaper Pants Manufacturing Machine Production Line

Read more