Diapers Elastic Spandex Yarn Constant Tension Controlled Unwinding System

Diapers Elastic Spandex Yarn Constant Tension Controlled Unwinding System

Product Details:

Features

- This device accurately detects the tension of fiber and ensures the feeding of constant tension under any processing conditions by precisely controlling the motor speed.

- It can be applied to all production equipment that requires constant tension fiber input.

- Stable operation of production at high line speeds is possible.

- OLED display with real-time data monitoring and displaying tension values.

- Fast response to the change of production speed.

- Wide tension setting range: 0.5-99.9g (0.1g accuracy).

- High accuracy and responsiveness tension sensor.

- Terminal controllers can be equipped for centralized adjustment of single or multiple tension controllers.

Benefits

- Minimize static contacts and significant reduction of spandex stress, breakages, and the machine stops decrease.

- Minimize elastic yarn breakages, and reduce elastic yarn eastes during bobbin change overstep.

- Minimize machine operator time for production control and empty spools replacement.

- Production process efficiency maximization ensures a continuous process cycle at simultaneous high production capacity and minimizes machine stops.

- Ensure the highest diaper quality, in terms of desired elasticity features.

Fiber Constant Tension Unwinding Device

- Tension sensors: high accuracy and high responsiveness.

- Feeding wheel: driven by servo motor, high response speed, the main feeding speed: 1020 m/min.

- Separator: separates multiple coils of fiber for stable operation of the feeding wheel.

- Operating and alarm indicators: operating status – blue light flashing, alarm status – red and blue lights flashing alternately.

- Operating buttons: for operating functional status, setting, and calibration.

- OLED display: the real-time display of fiber tension variations, set values, and average values.

- Tension controller: receives the tension sensor analog signal, through analog to digital conversion to the control system, servo motor drives the feeding wheel and displays real-time parameters on OLED at the same time. Use the control button to adjust the operating status.

Working Principle

- The fiber passes through the tension sensor to detect the current material tension value, which converts the analog signal into a digital signal and inputs it to the controller, which adjusts the speed of the servo motor in real-time according to the set standard tension to keep the wire at a constant tension supply.

- The OLED display shows the change of the current tension value and the working status of the machine in real-time.

- Four buttons on the side of the machine are used for function operation and parameter setting of the tension controller.

Terminal Controller

Monitor each group of controller operation parameters, can access 12 controllers at the same time, display the working status, and set parameters.

- High speed

- Versatile

- Reduce labor

- Less maintain

- Efficient

- Easy operation

Multi-loop Management Unit

This management unit can drive 12 tension controllers at the same time, automatically identify the controller access, can realize real-time data transmission between the terminal controller and multiple tension controllers, and output alarm signals under abnormal conditions.

Elastic Constant Tension Unwinding Frame (Matrix Cube) – Customizable on request

Controller Technical Parameters

- Power supply: 24VDC±10%

- Operating power: 5-25w

- Operation speed: 1020m/min

- Feeding wheel diameter: 50mm

- Alarm output: relay output

- Working environment: 10℃ ~ 40℃

- Maximum humidity: 80%

- Controller size: 160x75x83mm

Tension Sensor Technical Parameters

- Power supply: 15VDC±10%

- Operating current: 20mA (max)

- Analog output: 0.5 ~ 10V

- Working temperature: 10 ~ 50℃

- Storage temperature: -25℃ ~ 85℃

- Tension range: 0.5 ~ 99.9g

Applications

- Baby diaper manufacturing process

- Adult diaper manufacturing process

- Pull-up diaper manufacturing process

- Period panties manufacturing process

Related products

-

High Speed Disposable Compressed Towel Tablets Making Machine

Read more -

Automatic Maternity Pads Making Machine

Read more -

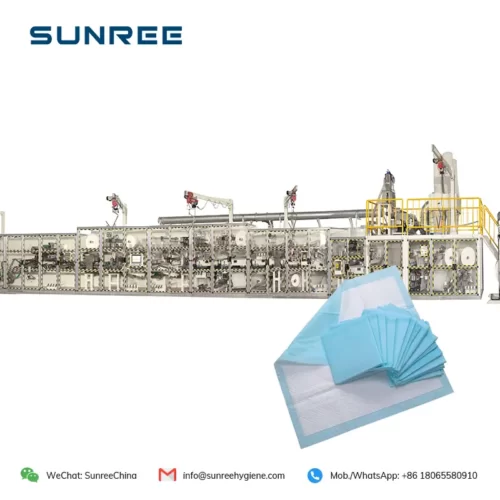

Full Servo Automatic Disposable Adult Bed Mattress Pet Underpads Under Pads Making Machine Production Line

Read more -

Fully Automatic T-type Baby Diaper Pull-ups Pant Making Machine Production Line

Read more