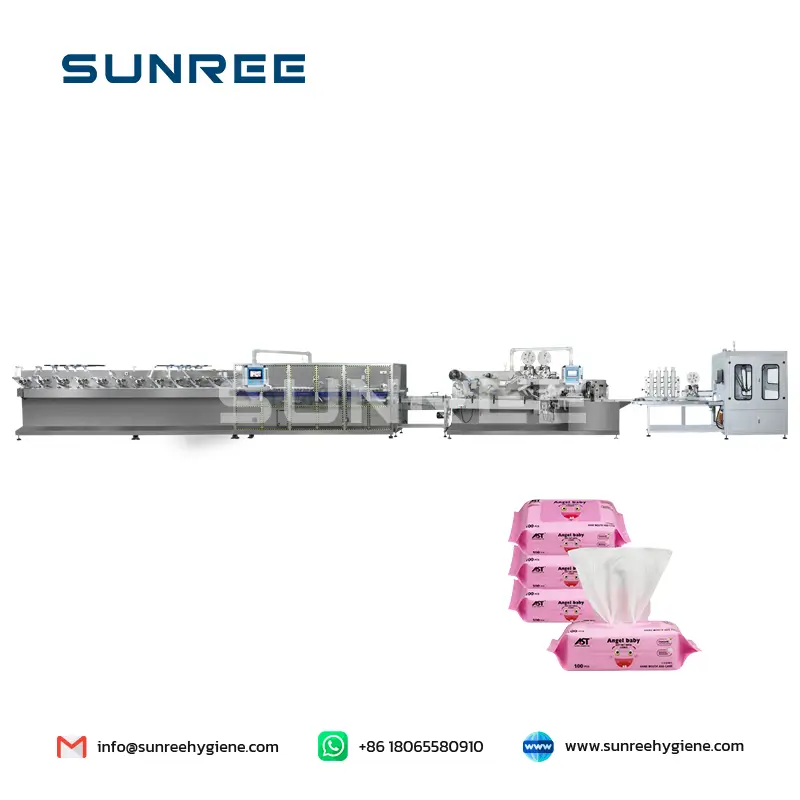

Automatic High Speed Big Pack Wet Wipes Machine

Automatic High Speed Big Pack Wet Wipes Machine

Product Details:

Related products

-

Automatic Spunbond Hot Air Topsheet Nonwoven Perforating and Embossing Machine

Read more -

Diapers Elastic Spandex Yarn Constant Tension Controlled Unwinding System

Read more -

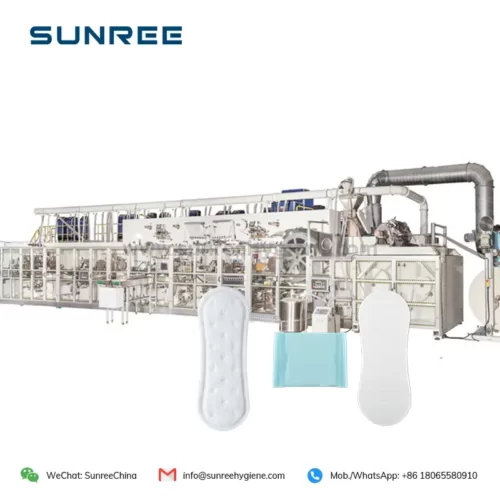

Full Servo Automatic Feminine Pantyliner Panty Liner Shield Making Machine Production Line

Read more -

Fully Automatic I-shaped Open Type Children Baby Diaper Production Line

Read more