SPUNBOND NONWOVENS FOR PERSONAL HYGIENE PRODUCTS

Manufacture excellent comfort, softness and dryness hygiene products with our versatile spunbond nonwoven solutions. Enhance brand owners’ confidence with leading-edge solutions that set you apart.

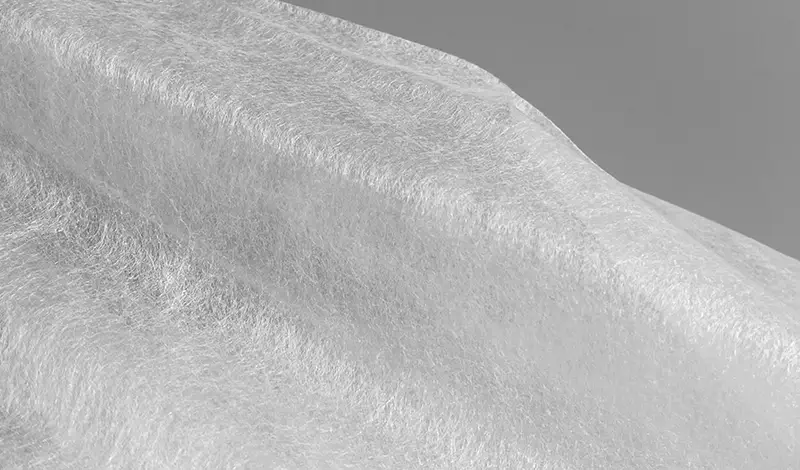

What is Spunbond Nonwoven

Spunbond nonwoven is a type of nonwoven made using a process where continuous filaments of polymer (like polypropylene, pp/pe) are spun and directly laid into a web-like structure. The web is then bonded to create a strong, lightweight, and durable fabric.

Characterized by our SS, SSS and BICO spunbond nonwovens’ superior softness, excellent fiber distribution, and balanced MD CD tensile strength, and optimal physical properties, our nonwoven fabrics are used in key components of baby diapers, feminine sanitary napkins, pantyliner, nursing pads, lady protective underwear, adult incontinence briefs and pants, and more.

PRODUCTS

Our spunbond nonwovens categories: soft, super soft, cotton soft, silky soft and loft soft are designed to meet different needs. All can be used in hygiene products where low basis weight, high performance and softness are essential, such as topsheet, backsheet, barrier leg leak cuffs, core wrapping, waistband and closure systems.

SUNREE Topsheet SSS spunbond nonwoven with superior effects, hydrophilic enabling efficient liquid penetration to the absorbent core while keeping the top sheet relatively dry to the touch. It is engineered for softness, breathability, and skin-friendliness, ensuring maximum comfort while maintaining functionality. Plain, embossed and perforated nonwovens are available.

SUNREE Backsheet SSS spunbond nonwoven is hydrophobic, normally laminated with breathable PE film as a critical role in providing a barrier to liquid leakage, allowing vapor to escape while offering a comfortable and breathable with a cloth-like texture. We have different bonding patterns for specific purposes, i.e. dot, sesame, diamond.

SUNREE Core wrapping SSS spunbond nonwoven is hydrophilic and low basis weight, with better tensile strength than traditional carrier tissue. It helps maintain the integrity of the absorbent core, preventing superabsorbent polymer (SAP particles) or fluff pulp from migrating out of the core while allowing liquid to pass through efficiently.

SUNREE Waistband SSS spunbond nonwoven is hydrophobic and has various softness for choice, widely used in pull-up pants. It’s designed to provide excellent softness for delicate skin, reducing irritation and ensuring comfort for extended wear, as well as breathable air circulation to maintain comfort around the waist area.

SUNREE Embossed and Perforated spunbond nonwoven is expected to meet the growing demand for premium hygiene products in the market, offering high levels of softness and comfort, as well as visually appealing embossing or perforating patterns, to deliver a premium experience to the end consumer.

SUNREE Bi-component spunbond nonwoven is a perfect solution providing supreme silky softness and enhanced lofty, compared to traditional spunbond nonwoven. The base material is polyethylene/polypropylene or polypropylene/polypropylene.

Applications

Our products are key components in manufacturing disposable absorbent products like baby diapers, feminine sanitary pads, adult incontinence briefs and underpads.

- ① Topsheet

- ② Leg cuff

- ③ Elastic spandex

- ④ ADL

- ⑤ Absorbent core

- ⑥ Core wrapping

- ⑦ Backsheet

- ⑧ Waistband

- ⑨ Side tape

- ⑩ Frontal tape

TECHNOLOGY

It is an integrated one-step process – from raw material to nonwoven, spinning continuous filaments directly from polymers and laying them into a web structure. This process is efficient, cost-effective, and versatile.

Leveraging our existing spunbond technology platform, extensive expertise, and innovation approach, we have developed nonwoven with varying degrees of softness to meet the needs of diverse markets.

When properties like supreme silky softness and lofty touch are required, we utilize our bi-component spunbond technology. With this technology, the spunbond fibers are composed of polypropylene and polyethylene in shear or side-by-side configuration, where the polyethylene delivers enhanced silky softness and lofty touch characteristics.

No matter which product you need, we work with a long list of general characteristics of our nonwovens.

Manufacturing Process

It is a long way from resin to nonwoven in a spunbond process and attention to detail in every link of the chain is required.

Raw material preparation, 100% PP or PP/PE polymer resin and various additives like color masterbatch are used as the raw materials.

Extrusion, the raw materials are melted in an extruder at a specific temperature. The molten polymer is then pushed through spinnerets with thousands of tiny nozzles to create fine filaments.

Filament quenching, as the filaments are extruded, they are cooled rapidly using a steam of cool air. The solidifies the fibers.

Stretching/Drawing, the cooled filaments are stretched or drawn using high-speed airflow. This step increases the strength and reduces the diameter of the fibers, spunbond fibers typically have a diameter in the range of 13-17 μm (1.2-2.0 dtex).

Web formation, the drawn fibers are laid down on a moving conveyor belt to form a continuous web. The fibers can be randomly oriented (most common) or directionally laid for specific applications.

Thermal bonding, the web is thermo-bonded using heated rollers to form a final spunbond nonwoven, which involves: Passing the web through heated calender rollers that fuse the fibers together at points; Adjusting the temperature, pressure, and roller speed to control fabric properties like softness and strength.

Finishing and treatment, the bonded nonwoven fabric can be treated with surface or functional coatings such as hydrophilic finished for hygiene applications, hydrophobic treatment for water repellency, and antibacterial treatment for medical textiles.

Cutting and roll-up, The spunbond nonwoven fabric is scanned by cameras for quality control before being rolled onto shafts in large jumbo rolls, and subsequently slit into the required smaller width rolls and packed according to customer requirements.

QUALITY

Superior product quality is nothing but a good standard. It is reliability in every step of the process that is hard to come by.

We have formalized our working processes, and nine inspection process. We have developed a system ensuring best in class quality assurance, product quality and quality logistics.

In-line inspection camera, minimum distinguishable defect size of 1.0 mm2.

Daily spot check, real-time transmission and monitoring, picking out and recording in the slitting link.

Real-time monitoring of the stability of the test performance of the production process and experimental objects to ensure the sustainable and stable quality of the equipment process and product quality.

The result is accountability and traceability through every step of the production process – from raw material to final delivery.

We have the right technology and machinery, but it is responsible and quality-conscious employees in every link of the value chain that ensures our customers the high quality they expect in our products and services.

Continual improvements are necessary to exceed the expectations of our customers.

We honour customer expectations with regards to our products and services and ensure compliance with relevant legislation and statutory requirements.

To strengthen our market position and enhance our competitiveness, we are committed to:

- Working with continual improvements

- Exceeding the demands and expectations of our customers

- Specifying and communicating raw material quality with our suppliers

- Maintaining high quality throughout the value chain

Through information, education and training, we wish to ensure that all our employees:

- Are quality conscious and take responsibility for their own work

- Have the right and obligation to react to defects

The FAQs You Might Want To Know

These frequently asked questions mention almost answers you might want to know before buying our spunbond nonwoven fabrics. We hope these informations could help you make a better decision.

FAQ

Table of Contents

LOOKING FOR SOMETHING ELSE?

We have helped customers in more than 60 countries to be successful, our website hereby lists some of the products we have successfully supplied. Please note that this constitutes just a tip of the iceberg of our products and innovations. Our engineering team could develop specifically for you, please allow us to do this.

If you haven’t been able to find a product for your exact requirements, please contact us.