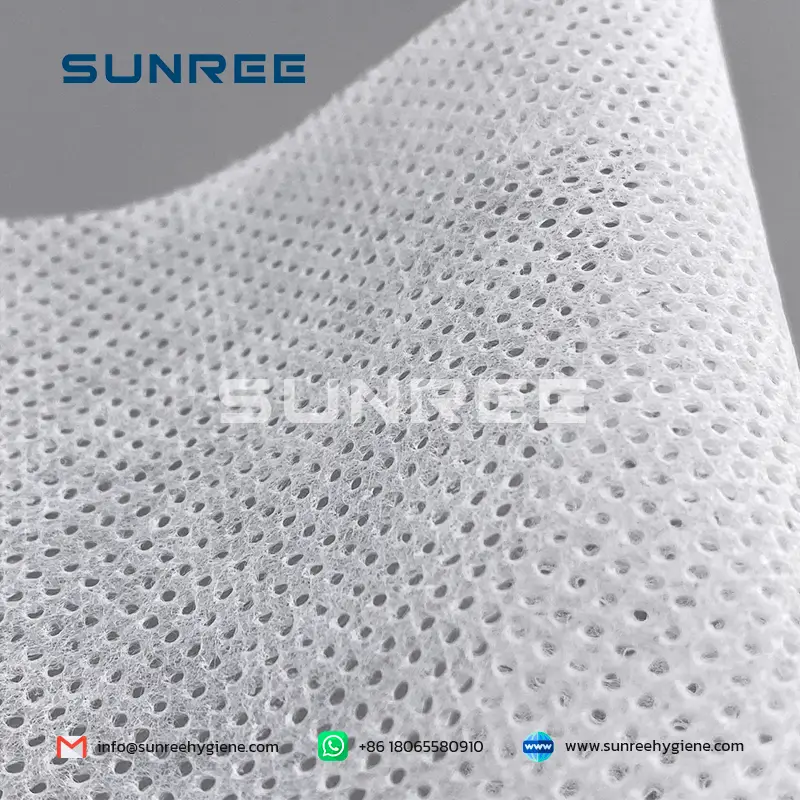

Perforated Hydrophilic SS SSS Spunbond Nonwoven Fabric

Additional information

| Material | Polypropylene |

|---|---|

| Basic Weight | 18-25gsm, or customized |

| Width | upon request |

| Color | White, or customized |

| Roll Diameter | Max. 1150mm |

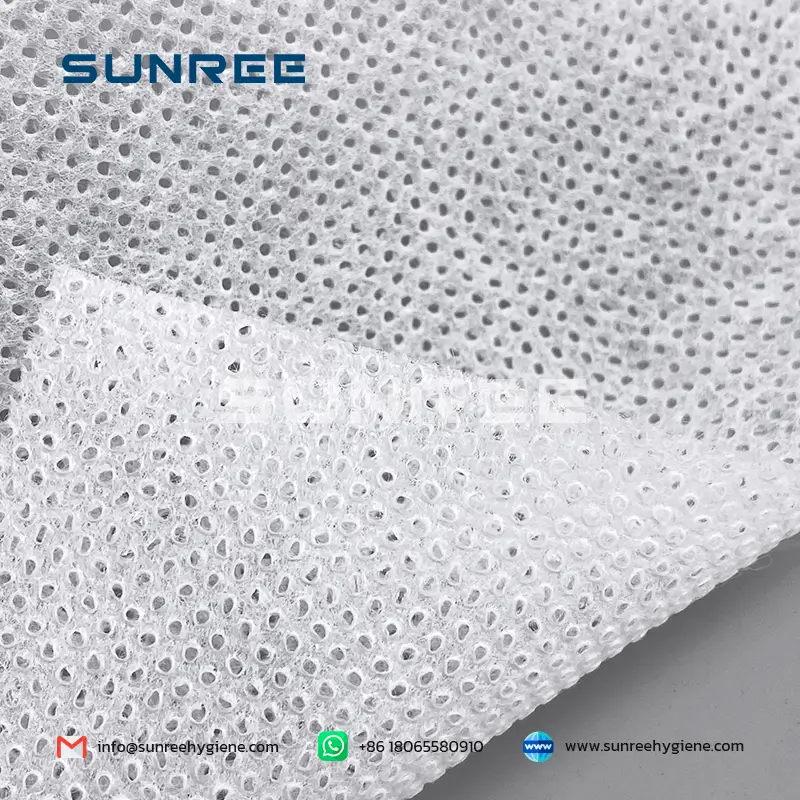

| Type | Emboosed, Perforated |

| Technics | Spunbond |

| Application | Baby diaper, Adult diaper, Sanitary napkins |

Share:

Perforated Hydrophilic SS SSS Spunbond Nonwoven Fabric

Product Details:

SUNREE perforated hydrophilic SS SSS spunbond nonwoven fabric is widely used as top sheet raw material of baby diaper, baby pull-ups pant, adult diaper, ladies pads, feminine sanitary napkins, underpads, etc.

Polypropylene spunbond nonwoven fabric is produced in the form of granulation of the raw material by melt extrusion method and filaments. It is made in one continuous process, Fibers are spun and then directly dispersed into a web by deflectors or can be directed with air streams. This technique leads to faster production speeds and cheaper costs. It can be combined with melt-blown nonwoven fabrics, conforming them into a layered product called SMS (spun-melt-spun) or SMMS, SSMMS, etc. with excellent water-repellent (hydrophobic) performance.

SUNREE has been offering our customers first-class 100% polypropylene hydrophobic and hydrophilic SSS SSSS spunbond, SMS SMMS spunmelt, perforated and embossed, soft and super soft nonwoven fabrics for different hygiene product needs. Our spunbond and spunmelt nonwoven fabrics are widely applied in the hygiene sector, such as baby diapers, adult incontinence briefs, underpads, feminine sanitary napkins, etc. We are definitely a reliable supplier of nonwoven fabrics as we have specialized laboratories set up within different production workshops, providing in-time and in-process control of each lot of the nonwoven produced.

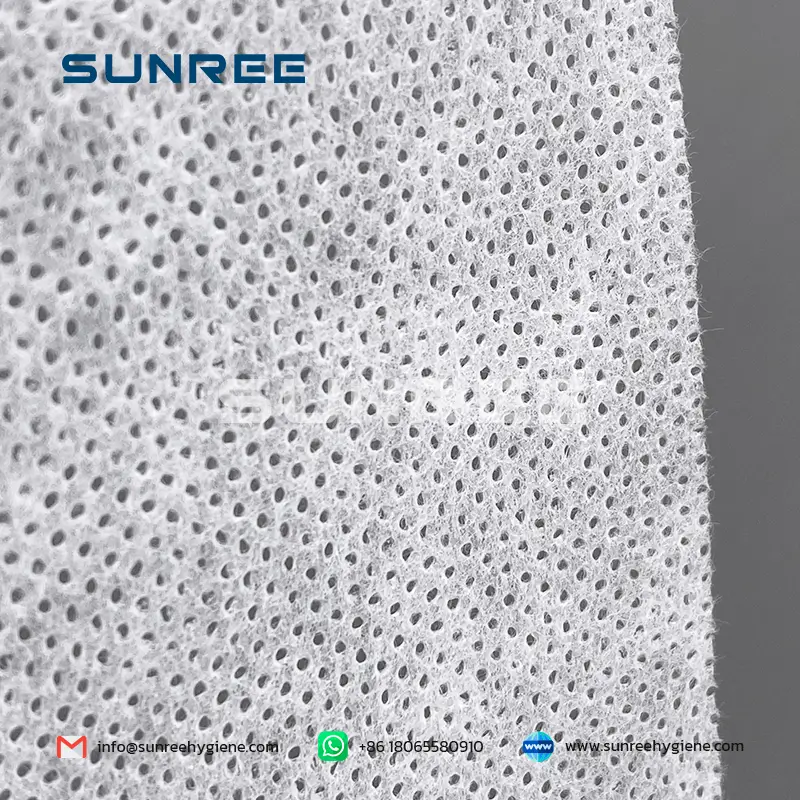

The production line adopts advanced die technology, and advanced online finishing equipment to produce single fiber with higher degree of fineness and SSS SSSS SMS SMMS nonwoven fabric with higher degree of softness. Nonwoven basis weight ranges from 9-50gsm. Post-finishing device allows hydrophilic and other functions, to meet the special needs of functional products from customer.

The production line is equipped with advanced Calender, cutting machine systems, excellent uniformity of web forming, precise pressure and temperature control, constant tension control, and precise cutting, to ensure the stability of SUNREE nonwoven and to provide customers with personalized nonwoven solutions.

In-line digital inspection system

- Cameras include transmission and reflection functions.

- Optical fiber for data transmission

- Effectively detect all web defects, such as holes, wraps, wrinkles and insects.

The scientific research center, the establishment of a sound quality assurance system and the advanced electronic moisture penetration and rewet meter instrument, softness tester, abrasion tester, the most advanced precision testing and measuring equipment, high precision, accurate, professional and strong, the production of each procedure carried our strict inspection process to achieve zero error production, to ensure that our nonwoven fabrics meet the standards.

Equal distribution of fiber in the surface fabric, balance in machine direction strength and cross direction strength, high final strength strength of the fabric due to the high strength of continuous filaments. When extraordinary entanglement and homogeneity is required the multiple layer, bond together nonwoven technology can be used. The balance between softness and MD and CD tensile strength is a solution successfully attained by SUNREE Nonwoven.

Application

- Super soft hydrophobic SSS SSSS nonwoven fabric, widely applied as waistband of baby pull-up pants, diapers back sheet lamination, with excellent softness, comfortable, good barrier properties, and tender care for baby’s delicate skin.

- Permanent hydrophilic SSS SSSS SMMS SSMMS nonwoven core wrap, better solution of SAP leakage, and stronger tensile strength to replace tissue paper. Ultrathin 9-11 gsm hydrophilic SMMS SSMMS nonwoven, makes the products lighter and safer.

- Permanent hydrophilic SSS SSSS nonwoven fabric, widely applied as the top sheet of baby diaper, adult incontinence diaper, underpads and feminine sanitary napkins, it can be embossed and perforated to provide more choices.

- Hydrophobic SMMS SSMMS nonwoven fabric for diapers leak cuff, high hydrostatic head pressure resistance and high barrier property, preventing side leakage. It is also used in core wrap, back sheet, diapers front and back ear.

- Hydrophobic S SS nonwoven fabric for diaper closure system, providing customers with different embossing options, sesame, diamond, plum blossom, etc. It can be PP or PE coated, providing better lamination performance.

SUNREE offers a wide range of quality nonwoven fabrics. As your nonwoven fabric supplier, we offer full capabilities to handle quick-change challenges, whether you need small or large quantities of nonwoven material.

For more information, view our nonwoven.

Ready to discuss your nonwoven needs? Contact us now!