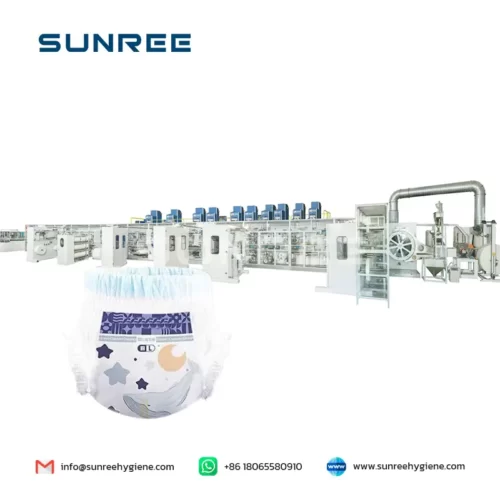

Dual-use Single and Double Layer Nonwoven Embossing Lamination Machine

Additional information

| Production Speed | 45-95 meters per minute |

|---|---|

| Automation | Auto changing roll infeed and outfeed without speed down |

| Power Consumption | approx. 200-400KW/10-12hours |

| Jumbo Roll Outer Diameter | 1200mm |

| Finished Roll Outer Diameter | 1050mm, or customized |

| Inner Core Diameter | 3/6 inch |

| Machine Dimension | approx. 7.3x3x2.3meters |

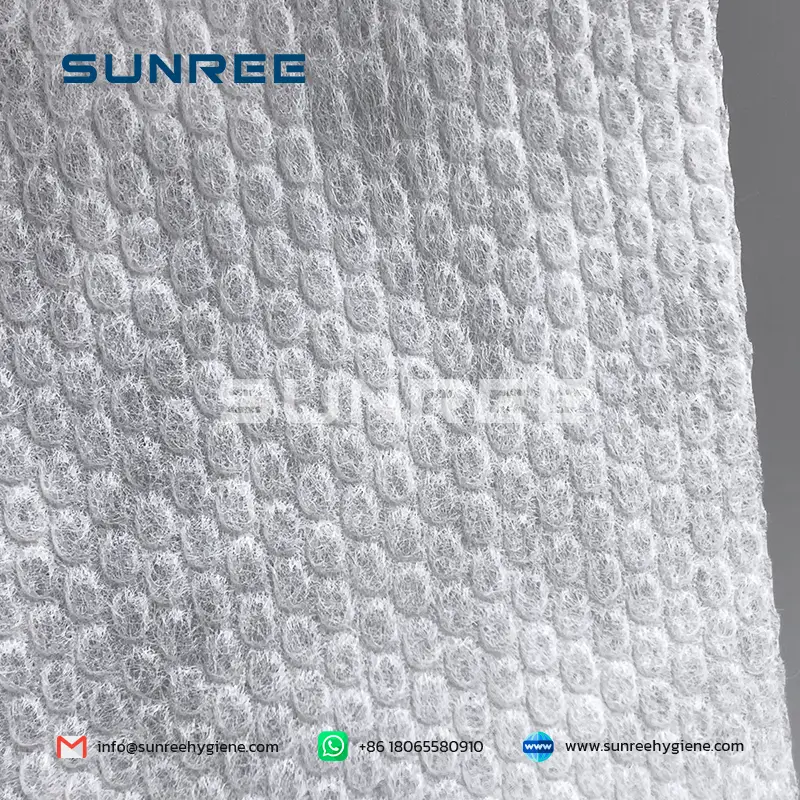

| Finished Product | Embossed Nonwoven, Perforated Nonwoven, Apertured Nonwoven |

Share:

Dual-use Single and Double Layer Nonwoven Embossing Lamination Machine

Product Details:

Main Parameters

- Dual-use: capable of the production of embossed and perforated 1-layer and 2-layer nonwovens

- Rewinding: automatic changing roll and splicing without speed down

- The finished roll can be unloaded by the rotating cantilever opening method, no need to lift the air shaft

- Dual motion control roll winding technology ensures “holes-to-holes” precision, and flatness on both sides of the nonwoven roll

- Easy to control the tightness of roll winding, suitable for kinds of nonwovens

- Easy to change the embossing and perforating mold roller, to minimize downtime

- Big roll diameter is workable, max. 1050mm or customized, reduce the material splicing during the production

- Low power consumption, approx. 200-400KW/10-12hours according to the width and pattern

- Production speed: 45-90 meters per minute (according to the embossed pattern)

- Embossing and lamination: ultrasonic or mechanical heat-pressing

Finished Product Specifications

- Jumbo Roll unwinding diameter: 1200mm

- Jumbo Roll width: 650-1650mm, or customized

- Inner core diameter: 76 or 152mm

- Finished roll diameter: 1050mm, or customized

- Roll width: 65-1600mm, or customized

Benefit

Embossed nonwoven which is expected to meet the growing premium market demand for high levels of softness and comfort. Our 3D embossing technology allows for enhanced softness and cushioning of the company’s nonwoven solutions for hygiene applications, offers visually appealing embossing patterns as well as the opportunity to deliver a premium experience to the end consumer.

Topsheet embossing improves fluid transfer and aesthetics by applying a textured pattern to the core. We have both ultrasonic and mechanical embossing capabilities to meet your aesthetic and product performance goals. Our high precision and robust units have a long service life, providing unrivaled value.

Related products

-

High Speed Disposable Compressed Towel Tablets Making Machine

Read more -

Double Layer Nonwoven Embossing and Lamination Machine

Read more -

Automatic Spunbond Hot Air Topsheet Nonwoven Perforating and Embossing Machine

Read more -

High Speed Full Servo Q-type Baby Pull-ups Pant Diaper Manufacturing Machine

Read more