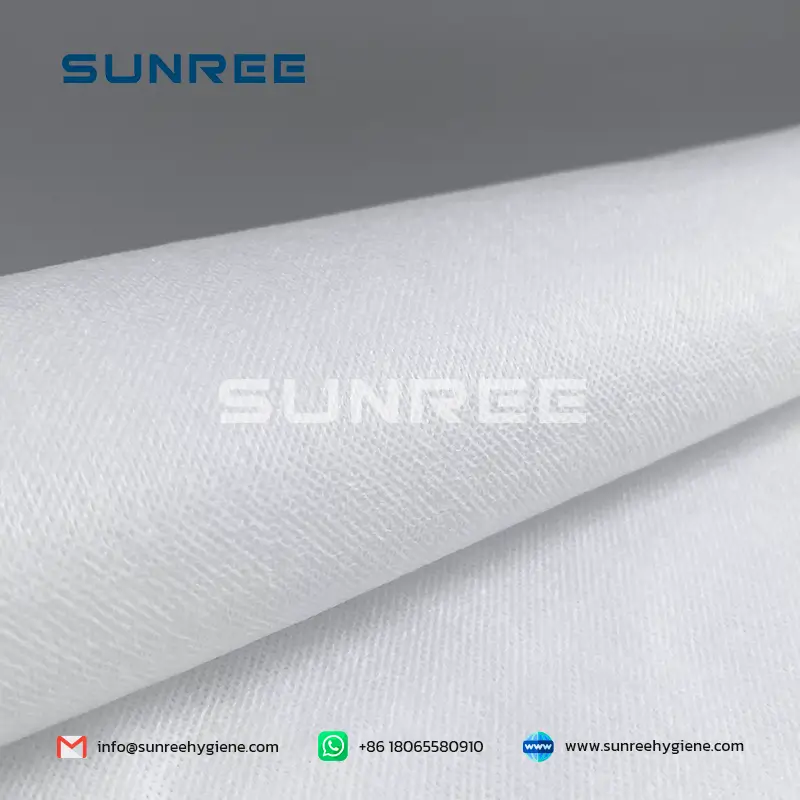

Perforated Mesh 100% Poly Lactic Acid PLA Spunlace Nonwoven Fabric

Additional information

| Material | 100% PLA |

|---|---|

| Basic Weight | 35-80gsm |

| Width | 80-2100mm, customized |

| Pattern | Customized |

| Color | White |

| Technics | Hydroentangle |

| Application | Wet wipes, Facial mask, Baby diaper, Sanitary napkin, etc. |

Share:

Perforated Mesh 100% Poly Lactic Acid PLA Spunlace Nonwoven Fabric

Product Details:

PLA spunlace nonwoven fabric is eco-friendly, without any chemical additives. It can be blended with other fibers to products with different functions, such as bamboo fiber.

Poly Lactic Acid is referred to as PLA, also known as Polylactide, is an aliphatic polyester. PLA is a biodegradable polymer material, by contains sugar, starch, cellulose and other biomass materials as raw materials, such as wheat, sugar beets, corn. Made of lactic acid by fermentation, and then made of lactic acid polymerization of polylactic acid polymer materials.

It comes from renewable biomass, has excellent biodegradability, can be completely degraded by microorganisms in the soil after disposal, generating CO2 and water, and does not pollute the environment. PLA itself belongs to the aliphatic polyester, has the basic characteristics of general polymer materials, and has good mechanical processing performance.

Composting

Polylactic acid (PLA) polymers undergo 2 steps degradation process: First, moisture and heat in the compost pile split the polymer chains apart, creating smaller polymers, and finally, lactic acid. Second, microorganisms in compost and soil consume the smaller polymer fragments and lactic acid as nutrients. The end result of composting is carbon dioxide, water, and humus, a soil nutrient. This degradation process is temperature and humidity-dependent.

Landfill

Conditions in landfills can vary considerably by geography, management practices, and age of waste. As a result of Belgium-based Organic Waste Systems performed two different series of tests spanning a broad spectrum of conditions. The first was at 21˚ C (69.8˚ F) for 390 days at three moisture levels. The second series of tests were designed to simulate high solids anaerobic digestion under optimal and significantly accelerated conditions and were performed at 35˚ C (95˚ F) for 170 days. Both series of tests were designed to represent an examination of what could happen under a range of significantly accelerated anaerobic landfill conditions.

Benefits

Higher barrier properties, breathability, transparency gloss and hardness, tensile and flexural modulus than conventional plastic resins.

Better biocompatibility. Its monomer raw material is L-lactic acid is the endogenous active substance in the human body, PLA products are non-toxic, non-exclusive, and can be absorbed by the human body, can be made into medical tissue skeleton materials and pharmaceutical carriers and safely used in the human body.

Fully degradable, degrades to carbon dioxide and water in 6-12 months when buried in the soil.

Application

Baby diaper, Nursing pads, Feminine sanitary napkins

The surface layer is made of PLA poly (lactic acid) nonwoven, the core layer is made of wood pulp fiber and super high water absorptive polymer watertight component, the backing film is made of air permeable PLA biomass and the product is wrapped by PLA nonwoven.

- Bacteriostatic and itching-free: the bacteriostatic rate for bacteria and fungi is higher than 98%.

- Air permeation and odor removal: Because of its unique fiber microstructure and the air permeable backing film developed by our own, it has excellent air permeation and feeling of dry and crisp, and function of reducing bad breath.

- Natural affinity with skin: It is derived from plants with weak acidity and has good biocompatibility, so it is especially suitable for use by people with allergic bodies.

For more information, view our nonwoven.

Related products

-

Unbleached Natural Color Mesh 100% Bamboo Spunlace Nonwoven Fabric

Read more -

EF Embossed Viscose Rayon PES Polyester Spunlace Nonwoven Fabric

Read more -

Embossed 100% Cellulose Woodpulp Flushable Nonwoven Fabric For Wet Wipes

Read more -

Color Plain Polyester Cellulose Woodpulp Carded-pulp Nonwoven Fabric

Read more