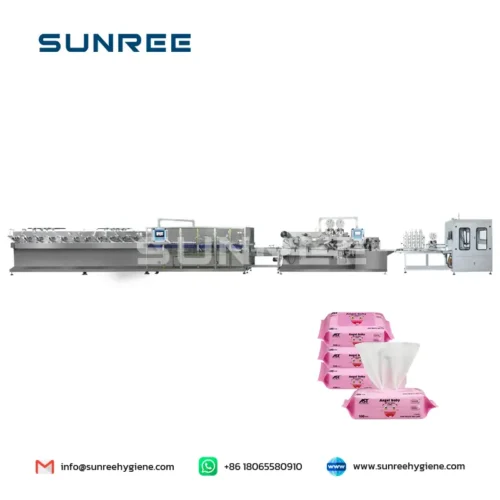

Fully Automatic T-type Baby Diaper Pull-ups Pant Making Machine Production Line

Additional information

| Production Speed | 500-800pcs/min, customized |

|---|---|

| Power Supply | 380V |

| Installation Power Capacity | 380KW |

| Air Consumption | 1800-4800l/minute |

| Qualified Rate | ≥97% |

| Product Width (min~max) | 385-420mm, customized |

| Product Length (min~max) | 400-550mm, customized |

| Dimensions (L×W×H) | About 45 x 9 x 4.5M |

| Machine Weight | About 95T |

| Finished Product | Baby Pants, Pull-ups Pants |

| Customization | Available |

Share:

Fully Automatic T-type Baby Diaper Pull-ups Pant Making Machine Production Line

Product Details:

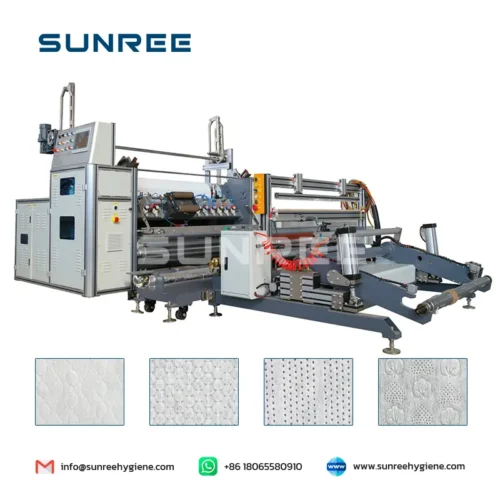

Modular Design

Flexible, allows customized configuration for the specific product required. Retrofit and upgrade kits can be easily installed and tailored in the future.

Compact Design

Smooth on-site start-up, easy operation, and easy maintenance.

Servo System

Each module is independently driven thus easing operators’ daily operations on the machine and ensuring adaptation to the raw materials used and environmental conditions.

Digital size change, ensure runs synchronously at the full process.

Program System

PLC, intelligent HMI touch screen man-machine interface.

Tension System

Tension control with buffer system, automatic web guiding system, to ensure materials stable working ar ZERO speed splice.

Core Forming System

Servo control for pulp and SAP feeding to precisely control the products with equal weight at different production speeds.

High speed saw crusher with well-mixed pulp and SAP to ensure good absorption and low rewet.

Safety System

Safety guard for operating side, emergency stop switch, security identifier, safety pull wire at driven side.